Boost Performance: Aftermarket Construction Parts Introduced

Wiki Article

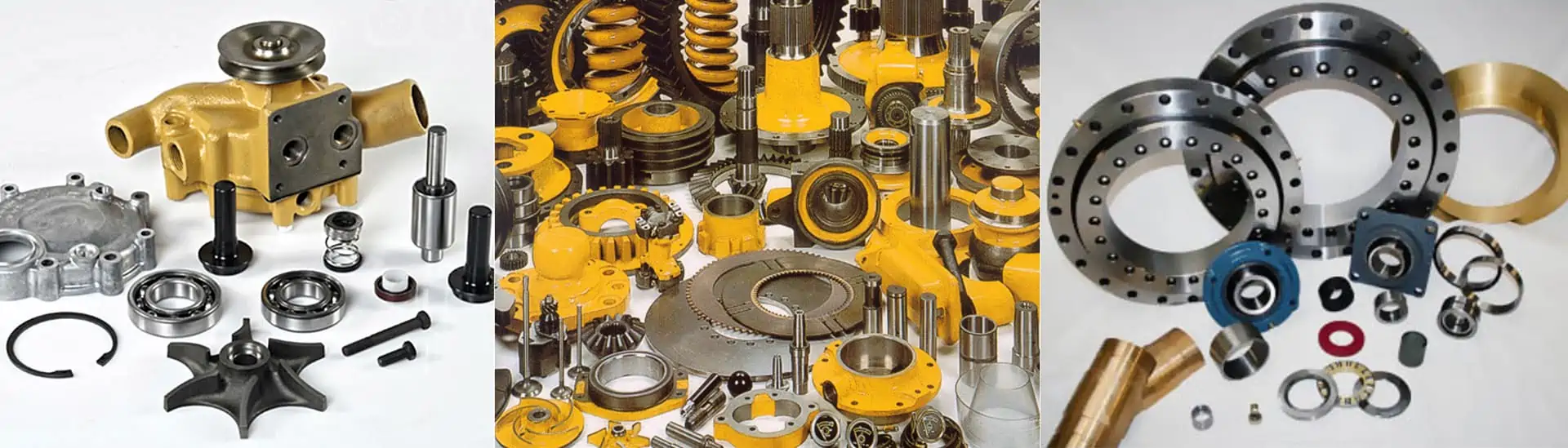

Increase Performance With Premium Aftermarket Construction Components for Heavy Equipment

Benefits of Costs Aftermarket Parts

When taking into consideration heavy equipment upkeep, going with costs aftermarket parts supplies significant benefits in regards to cost-effectiveness and performance dependability. Costs aftermarket parts are created to meet or surpass the initial equipment producer (OEM) requirements, ensuring a high level of top quality and compatibility. These components are typically a lot more inexpensive than their OEM counterparts, making them an affordable remedy for companies aiming to maintain their heavy machinery without endangering on efficiency.One of the essential benefits of costs aftermarket components is their capacity to supply dependable performance under requiring problems. Building and construction websites and commercial settings can be harsh environments, putting tremendous stress on equipment components. Costs aftermarket components are crafted to hold up against these obstacles, providing durability and long life that meet the needs of heavy-duty operations. By choosing costs aftermarket parts, services can minimize downtime, lower maintenance costs, and make certain that their equipment runs at peak efficiency.

Enhancing Equipment Performance

One of the considerable advantages of using premium aftermarket parts for hefty equipment maintenance is the improvement they bring to machinery efficiency in requiring functional atmospheres. Furthermore, costs aftermarket components can aid optimize fuel intake, minimize downtime for repair services, and decrease the danger of unexpected break downs, eventually leading to a smoother and extra efficient operation of heavy equipment in different building and industrial settings. Investing in premium aftermarket components is a calculated selection for companies looking to increase the efficiency and durability of their heavy equipment fleet.Cost-Effective Solutions for Upgrades

Implementing cost-efficient solutions for upgrades in hefty machinery maintenance can considerably influence operational performance and general performance. When considering upgrades, it's important to focus on financial investments that supply an equilibrium in between top quality and cost-effectiveness. official website One cost-effective remedy is deciding for premium aftermarket components that provide equivalent efficiency to initial tools producer (OEM) parts however at a lower price point. These aftermarket parts go through extensive testing to ensure they fulfill sector criteria and specifications, making them a trustworthy option for equipment upgrades.Routine upkeep and prompt upgrades can assist avoid costly downtime and expand the life-span of heavy machinery. An additional cost-effective technique is to purchase innovation upgrades, such as telematics systems, which can enhance devices monitoring and efficiency optimization - aftermarket construction parts. These systems enable real-time monitoring of device health and wellness metrics, enabling aggressive maintenance and decreasing the danger of unanticipated malfunctions

Boosting Equipment Long Life

Enhancing the sturdiness of heavy equipment is paramount for making the most of functional efficiency and minimizing total maintenance prices. Raising machinery longevity involves applying positive actions to expand the life-span of equipment. Routine maintenance routines, consisting of oil modifications, filter replacements, and evaluations, are necessary to Homepage prevent premature wear and determine possible issues before they escalate. Using premium aftermarket parts specifically made for heavy machinery can also add to lengthening the lifespan of devices. These components are often much more resilient and trusted than basic OEM components, providing raised resilience to harsh working conditions. Additionally, buying advanced innovations such as telematics systems can provide real-time information on machine performance, making it possible for drivers to deal with upkeep demands quickly and successfully. By prioritizing equipment longevity through a combination of preventive maintenance methods and high quality aftermarket parts, construction companies can enhance the efficiency and cost-effectiveness of their procedures while reducing downtime due to unanticipated malfunctions.Optimizing Equipment Functionality

To make sure the peak performance of hefty machinery, optimizing equipment performance is vital for construction companies intending to optimize operational performance and lessen downtime. Executing a preventative maintenance routine can help in detecting damaged parts or parts that may prevent the equipment's performance.Integrating efficiency monitoring devices can help in evaluating machinery usage patterns and determining areas for enhancement or change to maximize capability. By focusing on equipment functionality optimization, building business can improve efficiency, extend equipment lifespan, and ultimately accomplish greater returns on their hefty machinery investments.

Conclusion

When considering heavy machinery click to read more maintenance, choosing for costs aftermarket components supplies significant advantages in terms of cost-effectiveness and performance reliability.One of the considerable advantages of using costs aftermarket components for hefty equipment upkeep is the improvement they bring to equipment efficiency in requiring functional environments.To ensure the peak performance of heavy machinery, enhancing machinery functionality is important for construction business aiming to take full advantage of functional efficiency and lessen downtime. By focusing on machinery capability optimization, building and construction firms can boost productivity, prolong machinery life-span, and inevitably attain greater returns on their heavy equipment investments.

In conclusion, using premium aftermarket building parts for heavy machinery supplies many advantages, including boosted efficiency, economical upgrades, raised longevity, and enhanced functionality.

Report this wiki page